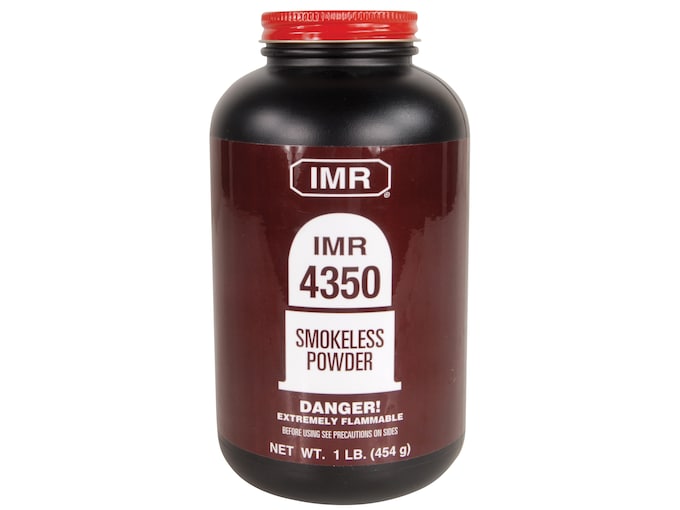

IMR 4350 Smokeless Gun Powder – Reliable Performance for Rifle Reloaders

IMR 4350 Smokeless Gun Powder – Reliable Performance for Rifle Reloaders

IMR 4350 Smokeless Gun Powder – Overview

IMR 4350 Smokeless Gun Powder is a versatile, medium-burning rifle powder designed for precision reloading. It delivers consistent velocities and excellent accuracy in popular cartridges like the .30-06 Springfield, .270 Winchester, and .338 Winchester Magnum.

This extruded powder features a stable burn rate, making it ideal for both hunting and target shooting. Its temperature-resistant formulation ensures reliable performance in varying climates, from extreme cold to high heat.

Key Features & Benefits

-

Medium Burn Rate: Optimized for mid-to-large rifle cartridges.

-

Temperature Stability: Consistent performance in -40°F to 125°F conditions.

-

High Energy Output: Maximizes velocity without excessive pressure.

-

Low Residue: Clean-burning formula reduces fouling.

Recommended Loads for IMR 4350 Smokeless Gun Powder

IMR 4350 works best with heavy bullets in cartridges such as:

| Cartridge | Bullet Weight (gr) | Charge Range (gr) |

|---|---|---|

| .30-06 Springfield | 150-220 | 54.0-58.5 |

| .270 Winchester | 130-150 | 53.0-57.0 |

| .338 Win Mag | 200-250 | 68.0-73.0 |

Always consult reloading manuals and start with minimum charges.

Why Choose IMR 4350 Smokeless Gun Powder?

Reloaders trust IMR 4350 Smokeless Gun Powder for its predictable ignition and smooth metering. Its extruded kernel structure ensures uniform flow through powder measures, reducing variation in charges.

This powder is also compatible with magnum primers, enhancing ignition consistency in large-capacity cases. Whether loading for bolt-action rifles or semi-autos, IMR 4350 provides dependable results.

Safety & Storage Guidelines

-

Store in a cool, dry place away from open flames.

-

Keep sealed in original container to prevent moisture absorption.

-

Follow SAAMI/CIP load data to avoid overpressure risks.